What is the one thing we have in common with the vast majority of businesses across the UK? We believe it is our drive to reduce our impact on the environment. As a manufacturer, we have already taken huge steps to reduce waste. We have removed single-use plastics, recover fluids, and recycle machined metal much more effectively. But we also need to reduce our energy consumption. Which brings us to our move to LED lighting in Middlesex Aerospace.

The End Of Fluorescent Tube Lighting

Good lighting is crucial in our business processes. It allows staff to be able to conduct visual inspections of components. And it is vital for everyone’s safety too. A badly-lit workplace is an unpleasant environment containing a haven for trip hazards and other injuries. So, for safety and quality, we must ensure we have the best lighting possible.

The To provide excellent lighting, our facilities have historically used fluorescent tubes. While these can reliably provide a good spread of light, they also have their issues, including:

- Efficiency: Although fluorescent tubes are more efficient than incandescent bulbs, they still consumer a lot of power. A typical tube producing 3,000 Lumens will use 55watts – plus another 5Watts for the ballast. Multiply that by the dozens we have in the factory and offices, and that’s a lot of energy.

- Short Working Life: In terms of their real-world operating times, flourescent tubes can be a bit of a lottery these days. You will see some claim they will work for up to 5 years, but we find any more than 2 years and they are on borrowed time.

- Recycling: As they contain mercury, fluorescent tubes are not good for the environment. In fact, tubes are commonly just dumped for incinerating.

Why Go LED?

If you compare LED lighting to the points above, three major benefits spring up.

First, LED lights are far more efficient. To produce the same amount of light as a fluorescent tube, LED systems use less than half the amount of energy. Plus, they don’t require a ballast, saving even more.

Second, LED lights last far longer. Real-world usage shows LED lighting to have a working life of up to 4 times more than a fluorescent tube. That’s around 8 years, meaning less business interruption from maintenance.

And third, LED lighting is more straightforward to recycle. The metal components can be stripped out and the electronics sent to the same facilities which recycle computers.

But perhaps the biggest incentive to upgrade from fluorescent to LED lighting is cost. Compared to our old tubes, LED lights need as little as 10% to keep our facilities bright, productive and safe. Which, in today’s climate of high energy bills, is a major plus.

Moving To A LED-Lit Future

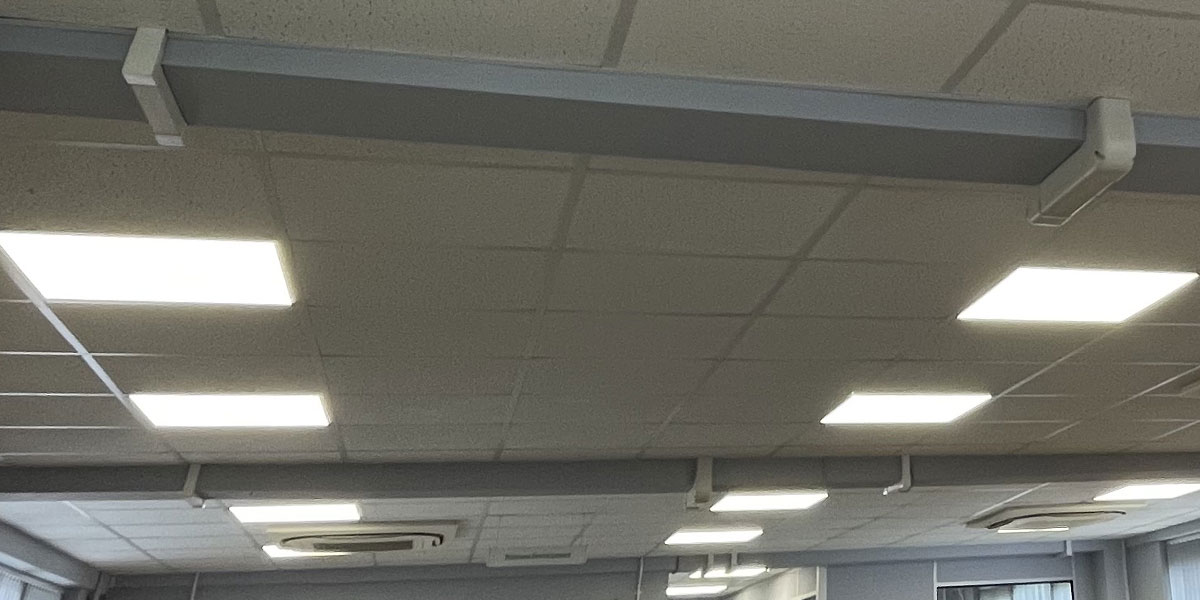

For these reasons we have been undertaking an ongoing programme of upgrading all the lighting currently in place in our facilities. During January we have been completing the final significant stage of this change to LED lighting. Now, all the office spaces within Middlesex Aerospace will feature LED technology, taking our total usage of LED systems to over 95%.

This shift from fluorescent to LED lighting is a major step-change in the sustainability of our business. From lowering our energy consumption to improving recycling – and reducing toxins being released – along with improving safety and quality, our move to LED lighting in Middlesex Aerospace simply can’t be overstated.